Product structure and features

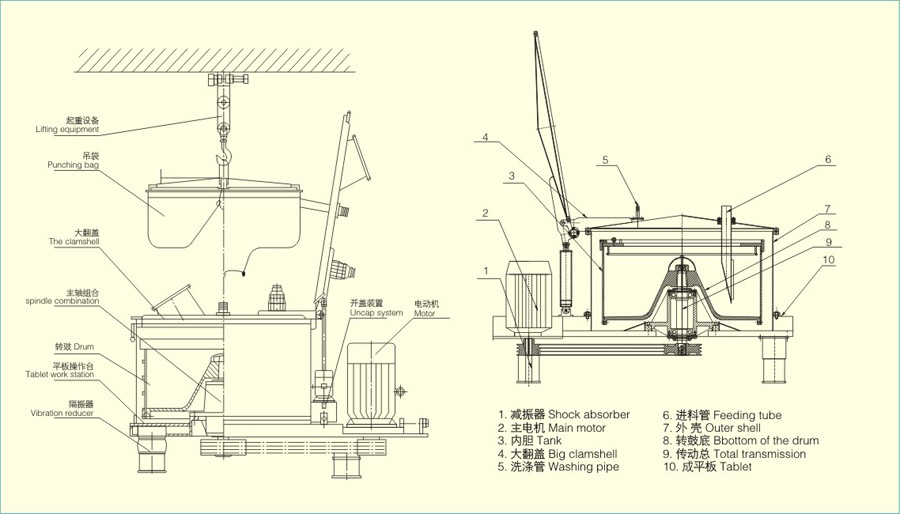

PSD centrifuges are all closed, intermittently operated, and off-site bag unloading filtration equipment. The material is added to the drum from the top. Under the action of the centrifugal field, the liquid phase passes through the filter medium and is discharged from the machine, and the solid phase is retained in the drum. After the machine is stopped, the liquid blocking plate and the filter bag are lifted out together with the sling and unloaded at the designated location. It has the characteristics of smooth start-up, adjustable separation factor, large capacity, high efficiency, simple operation, fast unloading, good safety performance, clean environment, and low labor intensity.

PSD centrifuges cancel the traditional hanging machine legs, use flat counterweights and high-viscosity damping isolators to absorb vibration, and are installed without foundation.

Optional configuration

■Cleaning spray system.

■Nitrogen protection system.

■RF admittance material range control.

■PLC program control.

■Hydraulic action system.

■Gas-assisted scraper.

■No foundation form (equipped with vibration isolation chassis + shock absorber).

■According to the anti-corrosion requirements of the separated materials, corresponding stainless steel materials (SUS304, 321, 316L, 904L, duplex stainless steel, titanium, etc.) are used.

Product Application

PSD centrifuge is an improved product based on SS three-legged upper discharge centrifuge. In addition to retaining the advantages of SS centrifuge, it also significantly reduces labor intensity, is quick to discharge, is easy to clean the filter bag, improves production efficiency, and avoids contamination and scattering of finished products caused by manual unloading.