Main uses of the product

Suitable for separating suspensions containing solid matter with a particle size greater than 0.005mm and a concentration range of 2-40%. Widely used in chemical, light industry, pharmaceutical, food, environmental protection and other industries. For example: oxalic acid, alum, aluminum hydroxide, ammonium bicarbonate, ammonium chloride, ammonium nitrate, ammonium sulfate, anthracene, antibiotics, barium chloride, barium carbonate, barium sulfate, benzene, benzoic acid, blood products, blue vitriol, borax, boric acid, lees, calcium carbonate, calcium citrate, calcium hydroxide, calcium nitrate, calcium oxalate, casein, cellulose, chrome yellow, clay, methyl cellulose, coal flotation waste, corundum, cotton wool, corn germ, edible oil, fish processing, mirabilite, glutamic acid, hops, pesticides, diatomaceous earth, herbicides, tartaric acid, sodium sulfate, carbon black, etc.

Main features

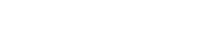

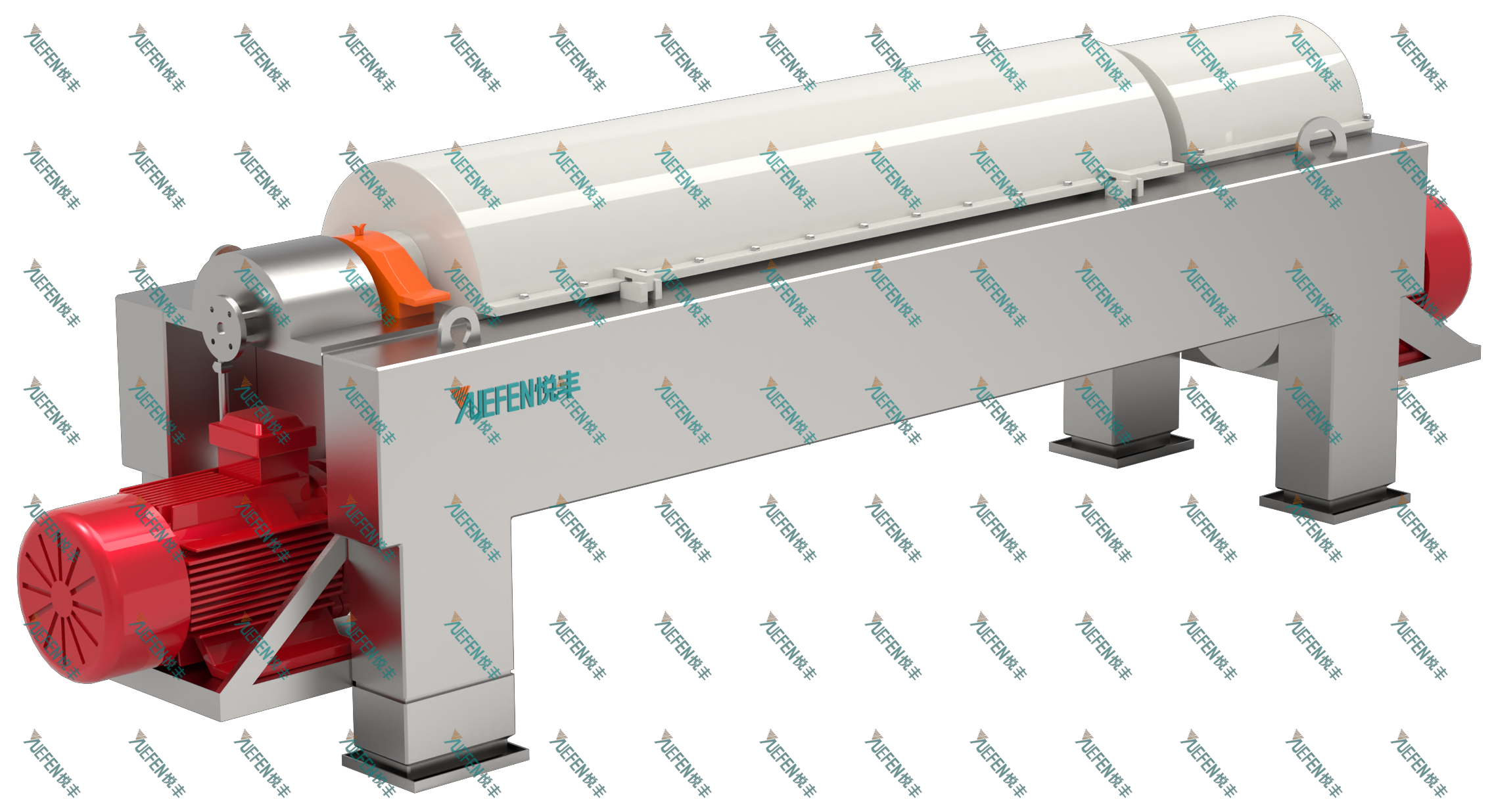

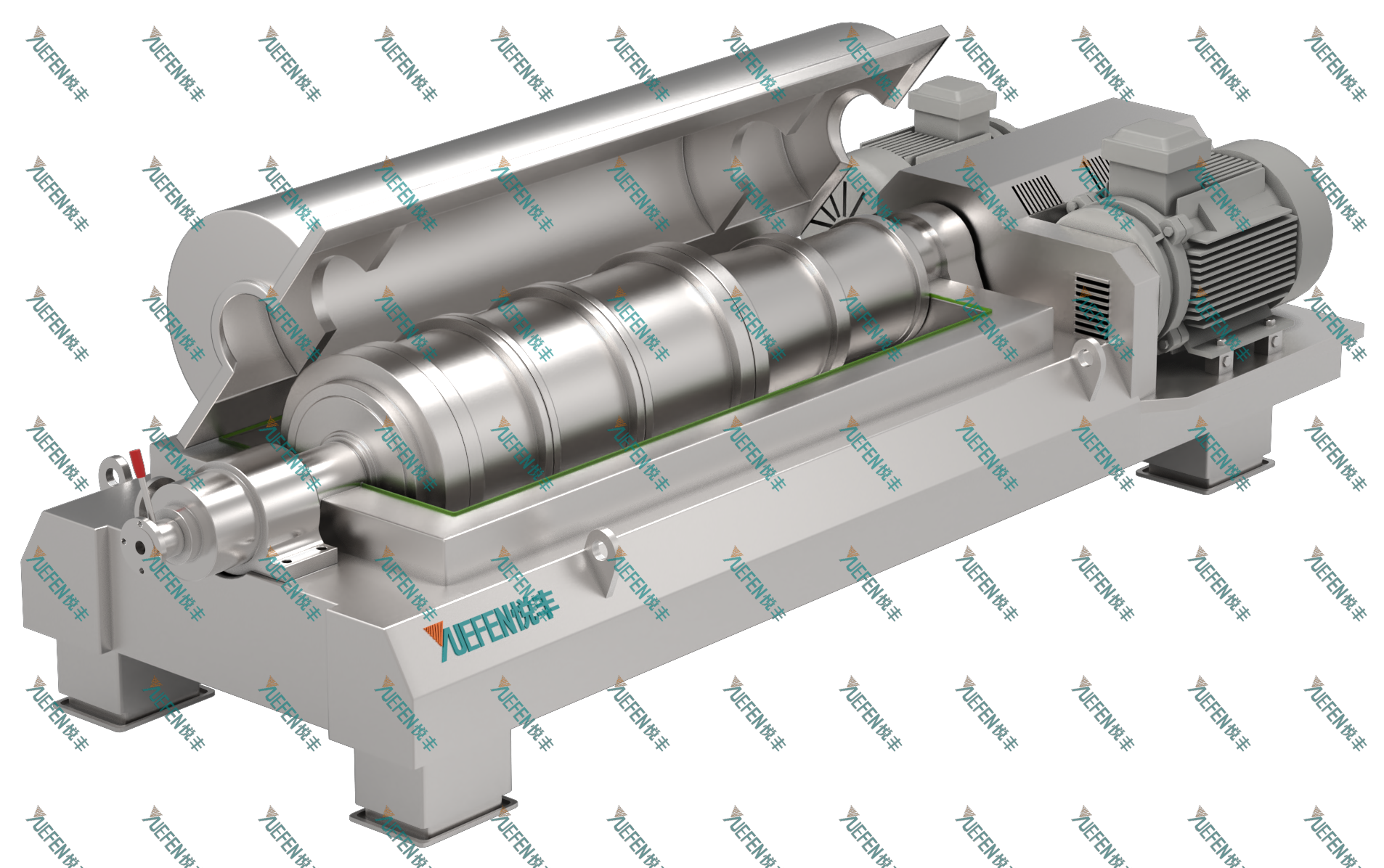

Horizontal screw centrifuge is the abbreviation of horizontal screw unloading sedimentation centrifuge. The horizontal screw centrifuge with mechanical differential is mainly composed of drum, screw, planetary gear differential, bearing seat, feed pipe, machine base, cover, main motor, auxiliary motor, electrical control system and various monitoring instruments. When the material enters the drum cavity of the centrifuge, it is driven by the high-speed rotating drum to rotate at high speed, so the material will be subjected to strong centrifugal force. The solid particles in the mixture have a large density and are subjected to a large centrifugal force. Therefore, the solid phase will be thrown on the inner wall of the drum to form a solid ring layer, while the liquid phase has a small density and is subjected to a small centrifugal force. It can only form a liquid ring layer inside the solid ring layer. Due to the different speeds of the screw and the drum, there is relative motion between the two (i.e., differential speed), so the screw will push the solids deposited on the inner wall of the drum to the outlet at the small end of the drum and discharge it, while the liquid phase will be discharged from the overflow port at the large end of the drum. The function of the differential is to form a certain speed difference between the drum and the screw.

Ordering Instructions

Material: The part in contact with the material can be ordinary stainless steel, special stainless steel, titanium alloy, etc.

Drive mode: electromagnetic speed regulating motor drive, ordinary motor or explosion-proof motor variable frequency drive, etc.

Differential speed selection range: 10-60r/min

Aspect ratio selection range: 2-4

Number of spiral heads: single or double

Can be designed and manufactured according to GMP specifications.

Main technical parameters: