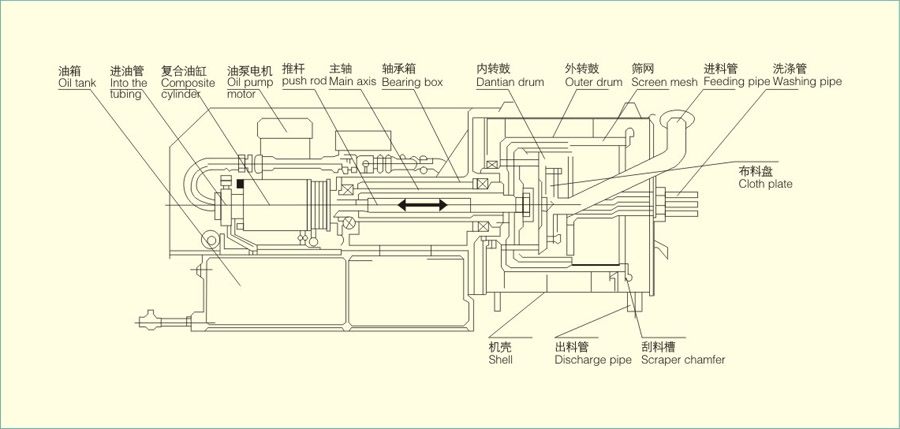

Product structure principle

The main motor drives the inner and outer drums of the set to rotate at full speed. The material is continuously introduced from the feed pipe and evenly distributed on the inner filter screen wall of the inner drum. Under the action of centrifugal force, the liquid phase passes through the filter screen and the filter holes of the drum wall and is discharged from the machine through the discharge pipe. The solid phase is retained in the inner drum to form an annular filter cake layer. While the inner and outer drums rotate at the same speed, the inner drum continuously reciprocates axially under the push of the piston, so the pusher plate pushes the inner drum filter cake layer to move outward intermittently and discharge from the inner drum, enter the outer drum for further separation and form an annular filter cake layer, and the outer end surface of the inner drum pushes the outer drum filter cake layer to move outward intermittently and discharge from the outer drum, and is discharged from the machine through the scraper trough.

Product features and uses

HR series centrifuge is a horizontal two-stage piston pusher, continuous operation filtering centrifuge. It can continuously perform feeding, separation, washing, unloading and other processes at full speed. It has continuous operation, stable operation, high separation factor, large production capacity and high output. It has the advantages of good washing effect, low moisture content of filter cake, and low solid content of mother liquor. It is suitable for separating suspensions with solid phase particles larger than 0.08MM and concentration greater than 35%. It is suitable for chemical, fertilizer, alkali, salt and other industries, especially for solid-liquid separation of sodium chloride, ammonium chloride, ammonium bicarbonate, sodium sulfate, ammonium sulfate, etc.

Special tips

■ Technical parameters shall be subject to the product manual.

■ When inquiring, please inform the customer in detail of the material characteristic parameters and working conditions.

■ According to the special needs of customers, we can adopt personalized design and manufacturing;

Material: The material contact part can be made of ordinary stainless steel, special stainless steel, titanium alloy, etc.

Motor form: Ordinary or explosion-proof single-speed motor can be used.

Liquid discharge method: Mother liquor and washing liquid can be discharged in mixed or split flow.

Filter gap width selection range: 0.08-0.40mm.

Can be designed and manufactured according to GMP specifications.

Other technical requirements can be agreed.

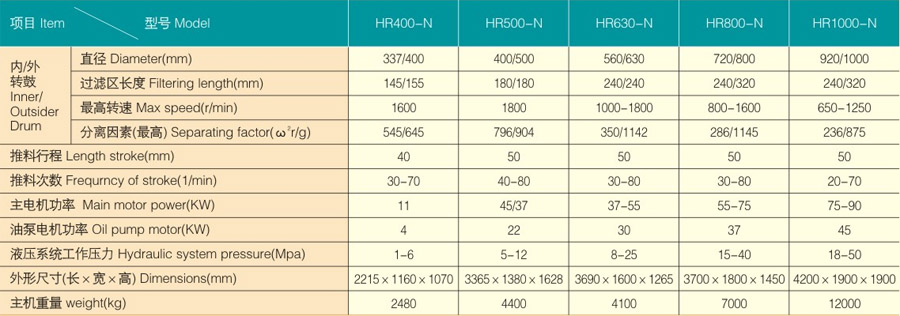

主要技术参数: