Features and Uses

■ PLC control, program setting, unattended automatic operation, monitoring of the entire process of feeding, primary filtration, washing, fine filtration and unloading.

■ Frequency conversion speed regulation, smooth start-up, adjustable separation factor.

■ The motor adopts the upper direct connection type to avoid the friction dust caused by the belt drive.

■ Large capacity, high output, improved production efficiency.

■ Energy consumption braking, non-contact braking method, no friction dust pollution.

■ Fully enclosed structure, seals are made of silicone rubber or fluororubber, and the inner cavity of the centrifuge is protected by nitrogen, which can achieve the requirements of closed explosion-proof.

■ Reasonable structural design, optional online cleaning system (spraying system), to ensure the cleanliness requirements, in line with GMP specifications.

■ Pneumatic (hydraulic) action system can be used for cleanliness and hygiene.

■ Radio frequency admittance material range control.

■ Optional gas-assisted scraper, no residual filter cake in the drum after unloading.

■ Safety protection: speed detection, over-vibration protection. Opening protection, motor overload and overheating protection, scraper rotation, lifting mechanical and electrical dual control, scraper drum linkage locking.

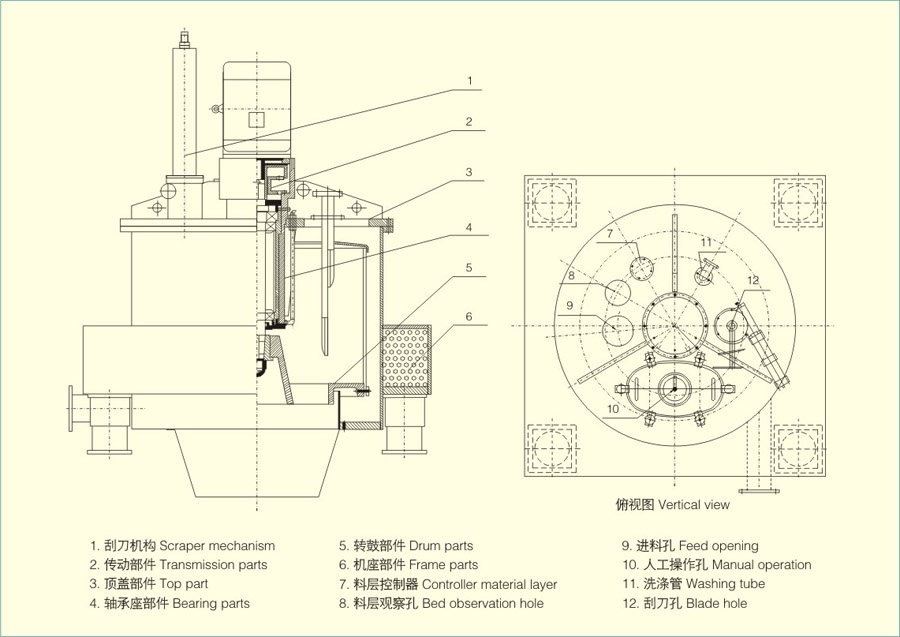

Standard manufacturing form

■Structure: The shell is equipped with a feed pipe, a washing pipe, an observation mirror, an exhaust port, an inspection hole, and a lighting hole; a closed structure, the drum, the shell, the flip cover and other parts are made of stainless steel. The machine base and other parts are carbon steel parts, and the surface is lined with stainless steel. The inner and outer surfaces of the drum, the shell, and the exposed parts of the machine are polished.

■All fasteners are stainless steel parts.

■PLC program control is adopted.

■Transmission and braking: hydraulic motor + inverter + energy consumption braking.

■Pneumatic (hydraulic) action system.

■PAUT adopts a flat structure and a liquid damping shock absorber.

Optional configuration

■Cleaning spray system.

■Nitrogen protection system.

■RF admittance material range control.

■PLC program control.

■Hydraulic action system.

■Gas-assisted scraper.

■No foundation form (equipped with vibration isolation chassis + shock absorber).

■According to the anti-corrosion requirements of the separated materials, corresponding stainless steel materials (SUS304, 321, 316L, 904L, duplex stainless steel, titanium, etc.) are used.

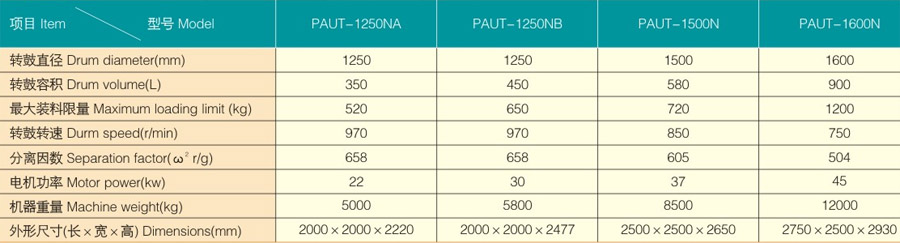

主要技术参数: