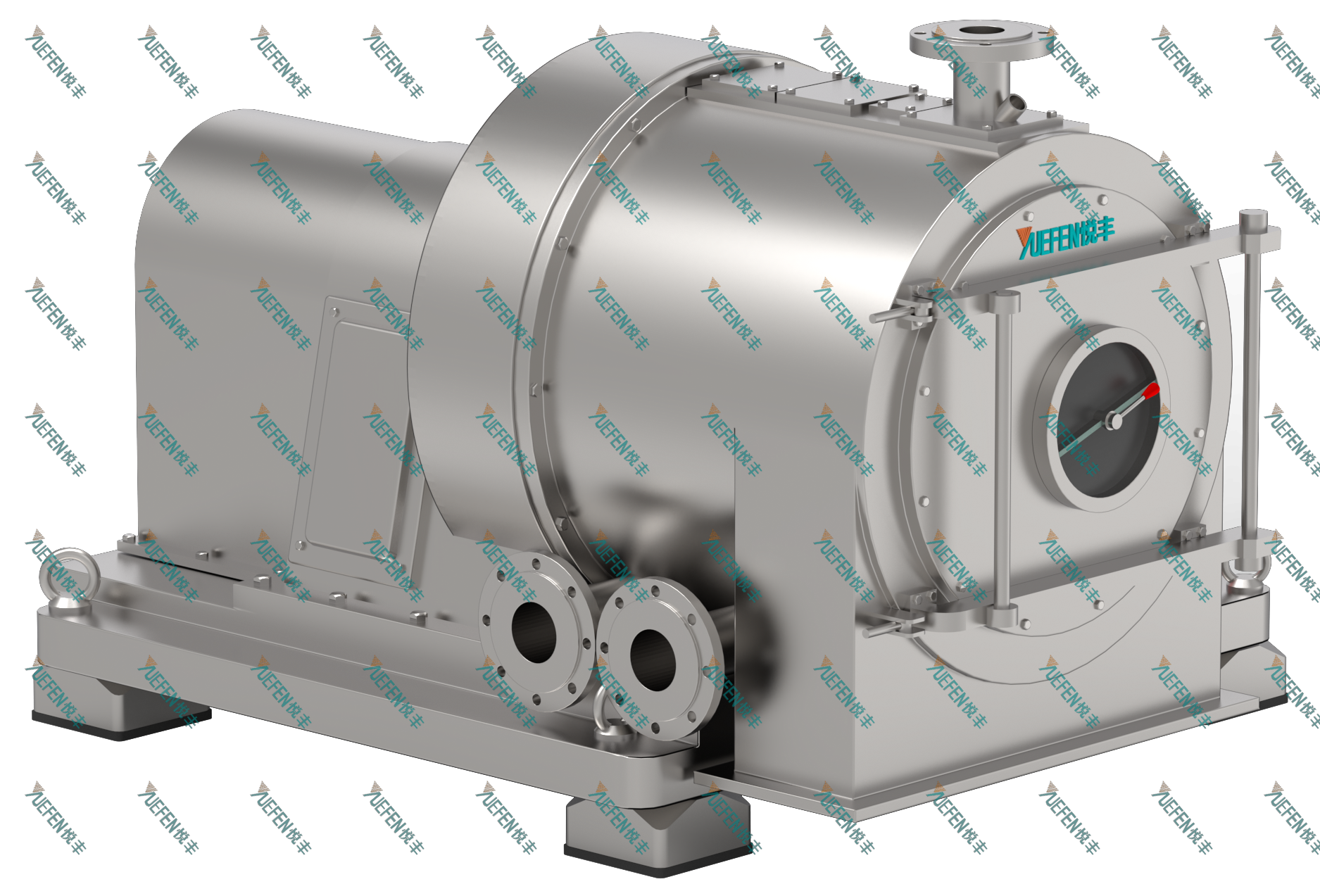

Working principle

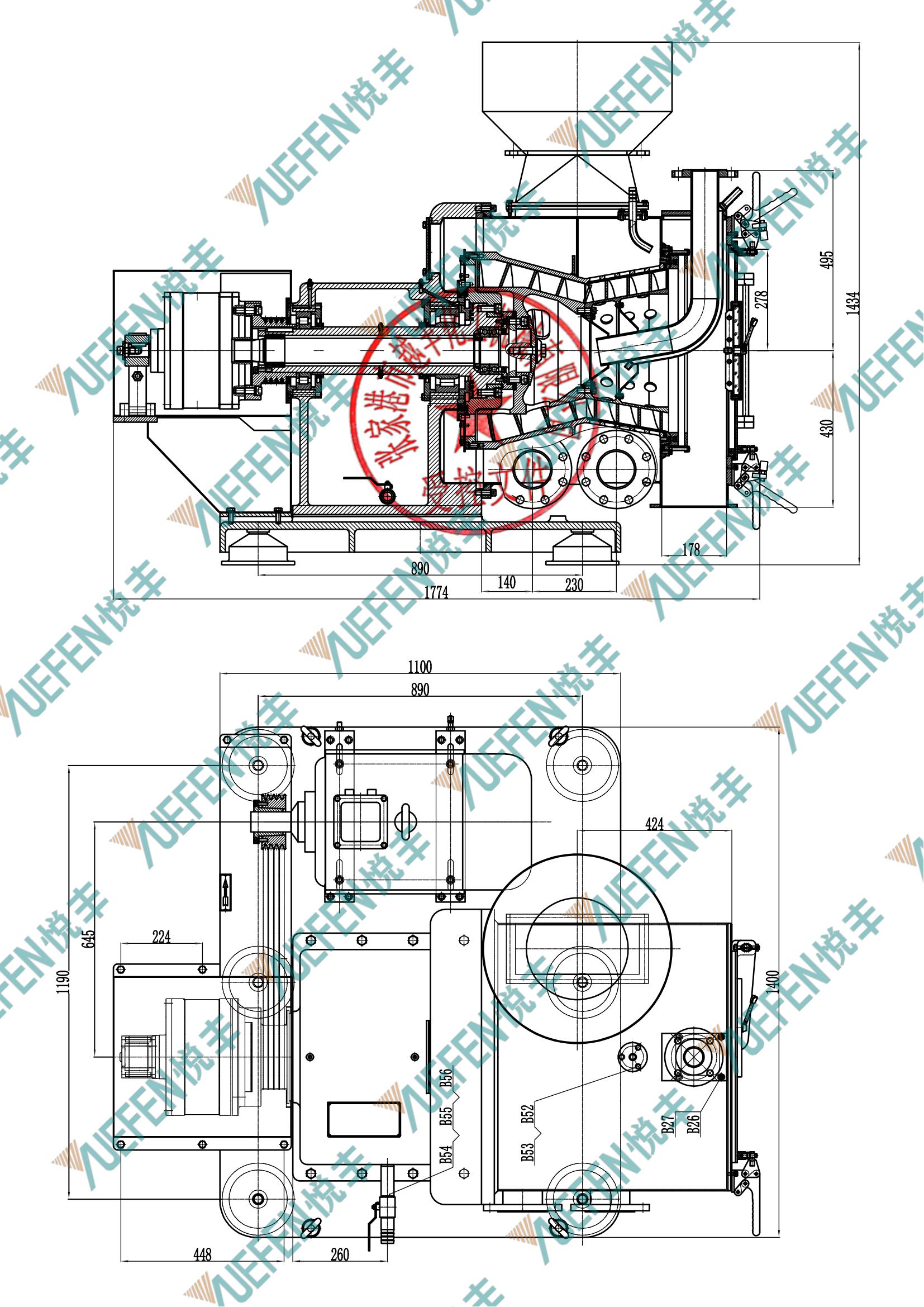

The main motor is started by the frequency converter. When the drum accelerates to the normal working speed, the liquid enters the drum cavity from the feed pipe, and the solid material is separated by high-speed cloth for secondary cloth separation. The secondary filtered material is filtered again to effectively improve the dryness of the material. Due to the centrifugal force field, the material first enters the drum multi-stage area, and most of the liquid overflows from the overflow port of the drum multi-stage area. The material after the drum multi-stage area is pushed from the drum multi-stage area to the filtration area by the differential speed of the inner and outer drums. The filtration area is cylindrical, and the inner side of the outer drum is equipped with a filter ( The filter gap can be selected according to the particle size of the material. The filter mesh gap of this machine is selected according to the solid material. After the material passes through the filter area, the remaining liquid phase in the material continues to be discharged from the machine body through the filter, while the solid phase is gradually pushed to the front filter area by the spiral blades wrapped around the inner drum due to a certain speed difference between the multi-head spiral body and the outer drum (the speed difference generated by the differential), and the torque to push the material is provided by the differential, which is mainly to overcome the friction resistance between the material and the inner wall of the drum), so that the solid phase material is discharged from the discharge port.

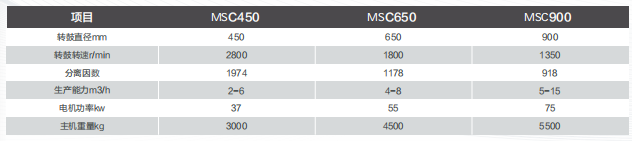

Technical parameters